Decoding the Spiral Wound Gasket Thickness Chart: A Complete Information

Associated Articles: Decoding the Spiral Wound Gasket Thickness Chart: A Complete Information

Introduction

With enthusiasm, let’s navigate by means of the intriguing matter associated to Decoding the Spiral Wound Gasket Thickness Chart: A Complete Information. Let’s weave fascinating info and provide contemporary views to the readers.

Desk of Content material

Decoding the Spiral Wound Gasket Thickness Chart: A Complete Information

Spiral wound gaskets are ubiquitous in industrial functions, offering dependable sealing options for an enormous vary of pressures and temperatures. Understanding the nuances of spiral wound gasket choice, significantly the essential function of gasket thickness, is important for making certain course of security and tools longevity. This text delves deep into the intricacies of spiral wound gasket thickness charts, explaining their goal, interpretation, and the elements influencing optimum thickness choice.

The Significance of Gasket Thickness

The thickness of a spiral wound gasket is not simply an arbitrary dimension; it is a essential design parameter straight affecting its sealing efficiency. A number of elements hinge on choosing the proper thickness:

- Bolting Load: A thicker gasket usually requires the next bolting load to attain the required compression. Inadequate compression results in leaks, whereas extreme compression can injury the gasket or the flange faces.

- Compression Ratio: This refers back to the proportion discount in gasket thickness after bolting. An optimum compression ratio is important for correct sealing; too little, and the gasket will not seal successfully; an excessive amount of, and it may well result in gasket failure.

- Floor End: The roughness of the flange faces impacts the required gasket thickness. Rougher surfaces necessitate thicker gaskets to compensate for the uneven contact space.

- Working Stress and Temperature: Larger pressures and temperatures demand gaskets with adequate thickness and materials properties to face up to the elevated stress and potential thermal growth.

- Flange Design: The kind of flange (e.g., raised face, ring kind joint) and its dimensions affect the suitable gasket thickness.

- Fluid Compatibility: The gasket materials have to be appropriate with the method fluid. Whereas thickness does not straight have an effect on compatibility, the choice course of usually considers each concurrently.

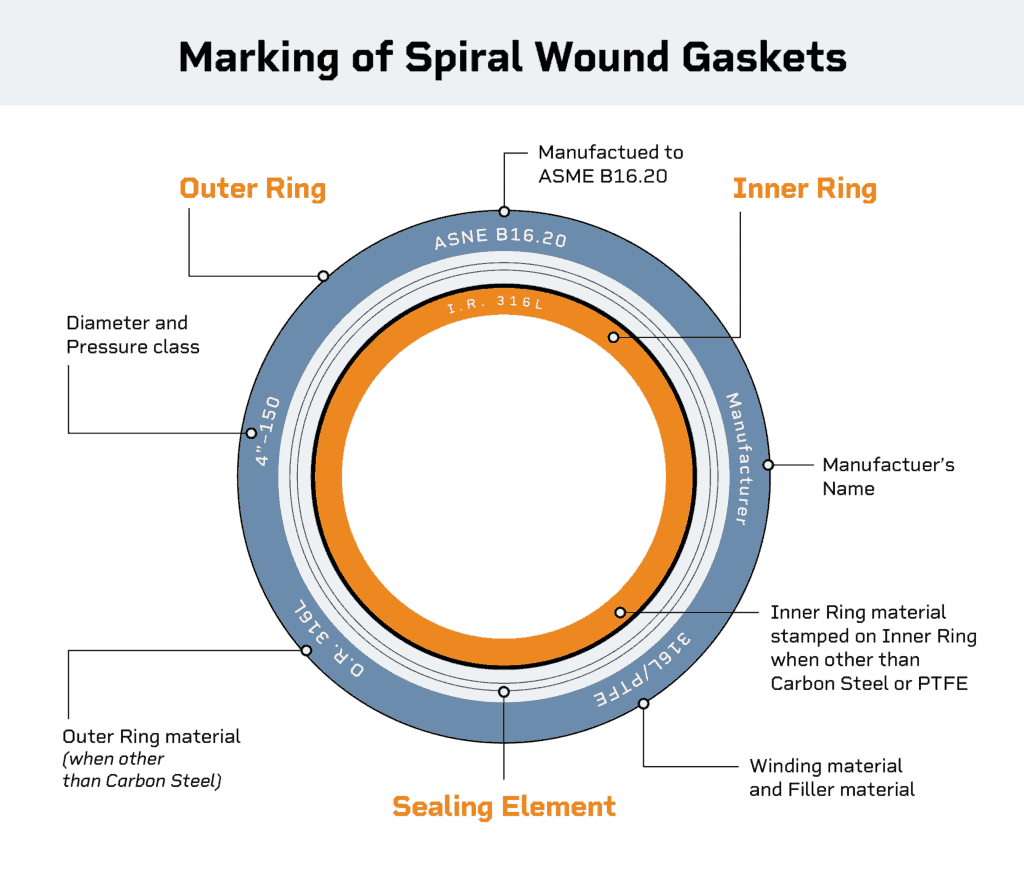

Understanding Spiral Wound Gasket Thickness Charts

Spiral wound gasket thickness charts should not standardized throughout producers. Every producer develops its personal charts primarily based on its particular gasket designs, materials properties, and testing information. Nonetheless, the underlying rules stay constant. These charts sometimes current gasket thickness as a perform of a number of key parameters:

- Nominal Inside Diameter (ID): The internal diameter of the gasket.

- Nominal Outdoors Diameter (OD): The outer diameter of the gasket.

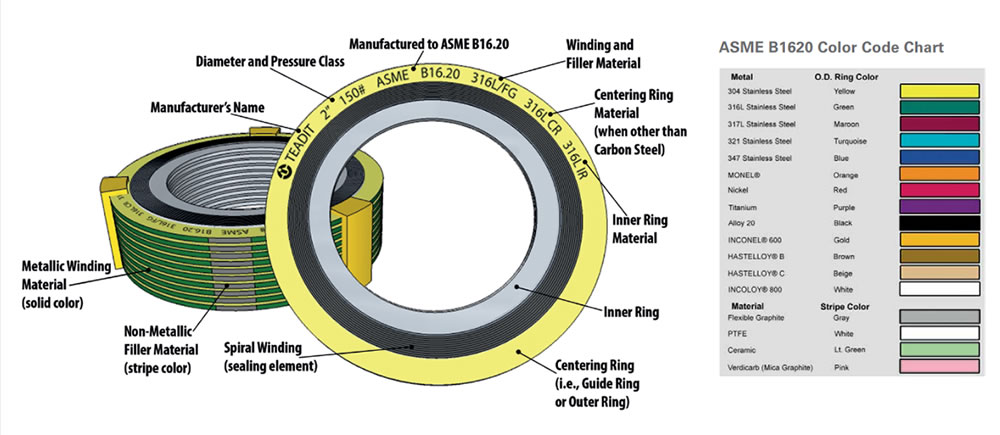

- Gasket Materials: Completely different supplies exhibit totally different compression traits, requiring various thicknesses for optimum sealing. Frequent supplies embrace graphite, PTFE, and numerous metallic supplies.

- Working Stress: The stress the gasket should face up to.

- Working Temperature: The temperature at which the gasket will function.

- Flange Sort: The chart could categorize gaskets primarily based on flange sorts (e.g., ASME B16.5, ANSI B16.47).

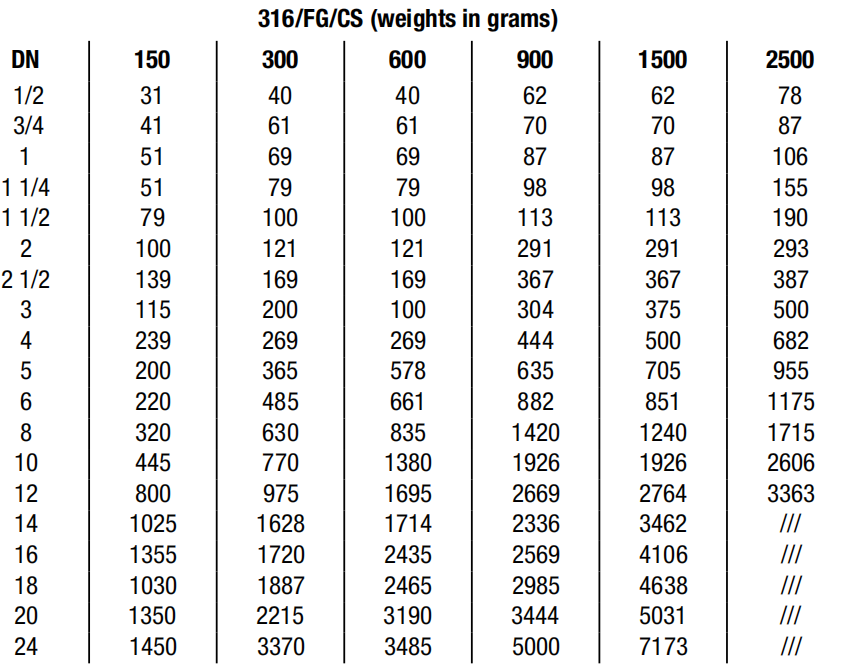

Decoding a Typical Spiral Wound Gasket Thickness Chart

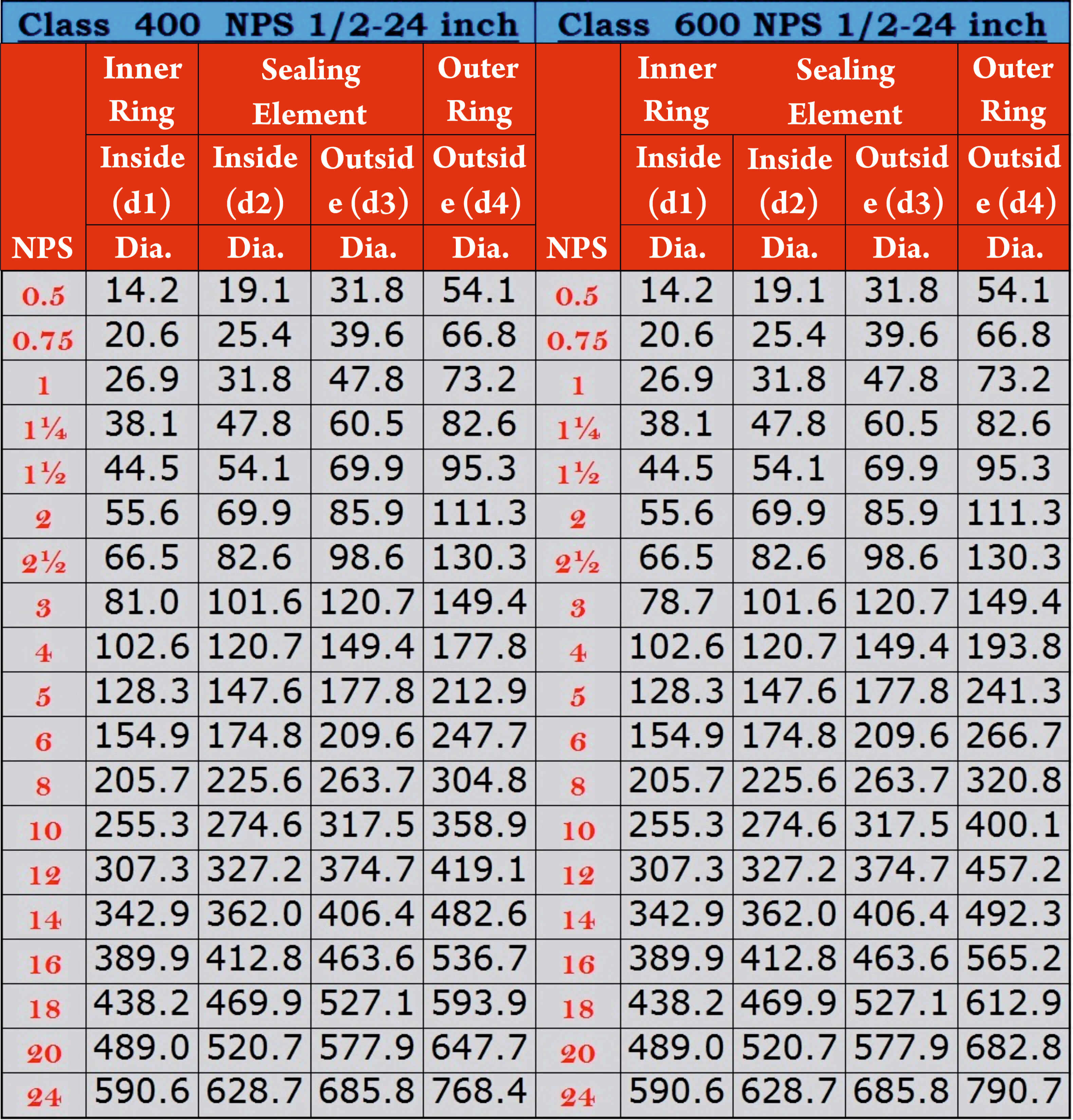

A typical chart could be offered as a desk or a sequence of graphs. A tabular chart would listing numerous gasket sizes (ID and OD) and supply corresponding thicknesses for various working circumstances (stress and temperature) and supplies. A graphical illustration would possibly present thickness as a perform of stress for a given materials, ID, OD, and temperature.

As an illustration, a bit of a hypothetical chart would possibly appear like this:

| Nominal ID (inches) | Nominal OD (inches) | Materials | Stress (psi) | Temperature (°F) | Thickness (inches) |

|---|---|---|---|---|---|

| 4 | 8 | Graphite | 150 | 500 | 1/8 |

| 4 | 8 | Graphite | 300 | 500 | 3/16 |

| 6 | 12 | PTFE crammed | 100 | 400 | 1/4 |

| 6 | 12 | PTFE crammed | 200 | 400 | 5/16 |

| 8 | 16 | Stainless Metal | 500 | 600 | 3/8 |

Components Affecting Thickness Choice Past the Chart

Whereas thickness charts present a beneficial place to begin, a number of extra elements require cautious consideration:

- Gasket Stress: The chart does not straight account for gasket stress. Finite component evaluation (FEA) or different engineering calculations could also be crucial for essential functions to make sure the gasket stays inside its allowable stress limits.

- Creep Leisure: Over time, gaskets can expertise creep leisure, a discount in compression drive. This must be accounted for, particularly in high-temperature functions, probably requiring a barely thicker gasket.

- Corrosion and Erosion: The gasket materials’s resistance to corrosion and erosion from the method fluid influences the choice. A thicker gasket would possibly present higher safety in corrosive environments.

- Floor Flatness: Important deviations from flatness on the flange faces could necessitate a thicker gasket to compensate for the uneven contact. Floor profiling is commonly advisable for essential functions.

- Security Issue: It is prudent to include a security issue into the thickness choice, particularly for high-consequence functions.

Past the Chart: Superior Methods and Issues

For advanced eventualities, relying solely on a thickness chart could be inadequate. Superior methods and issues embrace:

- Finite Component Evaluation (FEA): FEA can precisely predict gasket conduct beneath numerous working circumstances, optimizing thickness for particular functions.

- Experimental Testing: Testing with consultant gasket samples beneath simulated working circumstances can validate the chosen thickness and guarantee leak-tightness.

- Materials Choice Issues: The selection of filler materials inside the spiral wound gasket considerably impacts its efficiency and thickness necessities. Graphite fillers provide good sealing properties, whereas PTFE fillers present glorious chemical resistance. Metallic fillers improve energy and temperature resistance.

- Spiral Wound Gasket Design Variations: Completely different producers provide variations in gasket design, reminiscent of the kind of core materials, winding density, and outer ring design. These variations can affect the suitable thickness.

Conclusion:

Spiral wound gasket thickness charts are invaluable instruments for choosing the suitable gasket for a given software. Nonetheless, they need to be used along side a radical understanding of the working circumstances, flange design, and materials properties. For essential functions, superior methods like FEA and experimental testing are essential to make sure the chosen gasket thickness gives dependable and protected sealing efficiency. At all times seek the advice of with gasket producers and skilled engineers to make sure optimum gasket choice and forestall expensive failures. Do not forget that the chart is a tenet, not an absolute rule, and cautious consideration of all related elements is paramount for achievement. Ignoring these elements can result in gasket failure, tools injury, and potential environmental hazards. An intensive understanding of spiral wound gasket expertise and the even handed software of accessible sources are key to attaining dependable and protected sealing in industrial functions.

Closure

Thus, we hope this text has offered beneficial insights into Decoding the Spiral Wound Gasket Thickness Chart: A Complete Information. We hope you discover this text informative and useful. See you in our subsequent article!