Decoding the Schedule 40 PVC Friction Loss Chart: A Complete Information

Associated Articles: Decoding the Schedule 40 PVC Friction Loss Chart: A Complete Information

Introduction

With nice pleasure, we are going to discover the intriguing matter associated to Decoding the Schedule 40 PVC Friction Loss Chart: A Complete Information. Let’s weave attention-grabbing data and provide recent views to the readers.

Desk of Content material

Decoding the Schedule 40 PVC Friction Loss Chart: A Complete Information

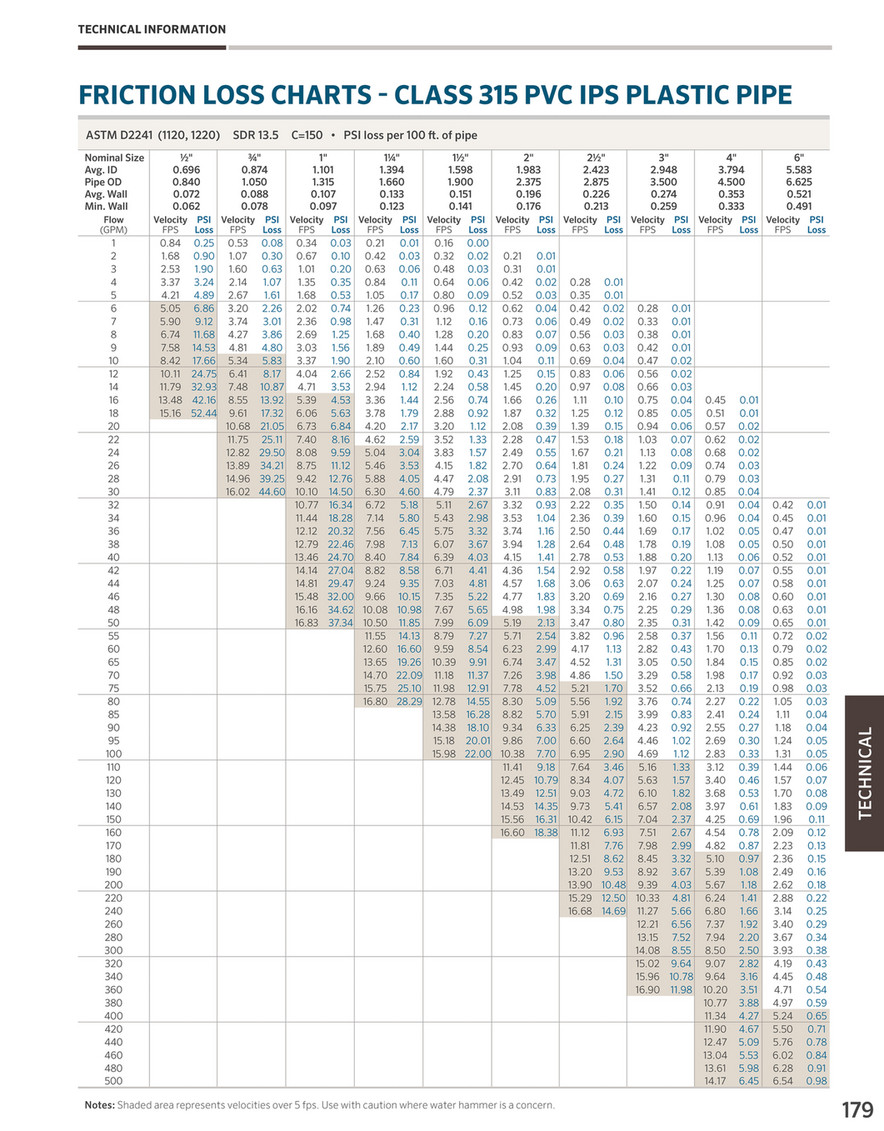

Schedule 40 PVC pipe is a ubiquitous materials in plumbing, irrigation, and industrial purposes as a result of its cost-effectiveness, corrosion resistance, and ease of set up. Nevertheless, understanding the friction losses inherent in fluid circulate by means of these pipes is essential for correct system design and environment friendly operation. This text delves into the intricacies of Schedule 40 PVC friction loss charts, explaining the way to interpret them, the elements influencing friction loss, and the way to apply this information in sensible eventualities.

Understanding Friction Loss:

When a fluid, reminiscent of water, flows by means of a pipe, it encounters resistance from the pipe’s partitions. This resistance, referred to as friction loss, causes a strain drop alongside the pipe’s size. This strain drop have to be accounted for in system design to make sure ample strain on the discharge level. Ignoring friction loss can result in inadequate circulate charges, system failure, and inefficient operation.

A number of elements affect friction loss in Schedule 40 PVC pipes:

- Pipe Diameter: Bigger diameter pipes provide much less floor space for the fluid to work together with, leading to decrease friction loss.

- Circulation Charge: Greater circulate charges enhance the speed of the fluid, resulting in elevated friction and consequently, larger strain drop.

- Pipe Size: Longer pipes naturally lead to higher cumulative friction loss.

- Fluid Viscosity: Extra viscous fluids (thicker fluids) expertise larger friction loss in comparison with much less viscous fluids. Water’s viscosity modifications barely with temperature, impacting friction loss calculations.

- Pipe Roughness: Whereas Schedule 40 PVC has a comparatively easy internal floor, microscopic irregularities nonetheless contribute to friction. This roughness is a minor issue in comparison with different influencing components in most purposes.

- Fittings and Valves: Elbows, tees, valves, and different fittings disrupt the sleek circulate of the fluid, creating extra friction loss past that of the straight pipe sections. These losses are sometimes expressed as equal lengths of straight pipe.

Deciphering the Schedule 40 PVC Friction Loss Chart:

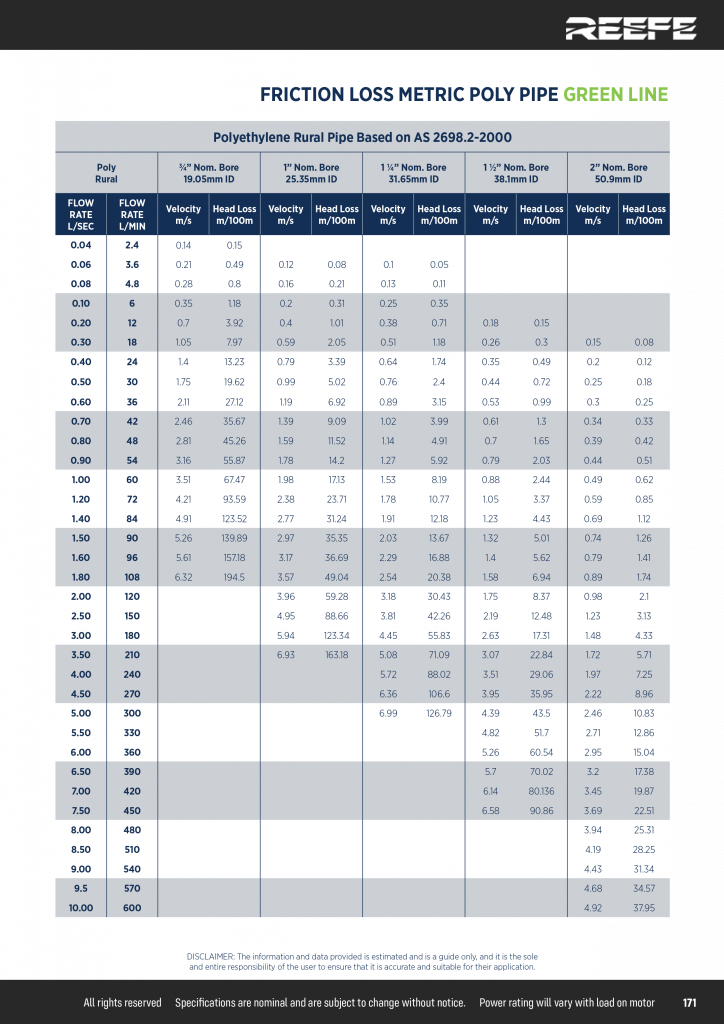

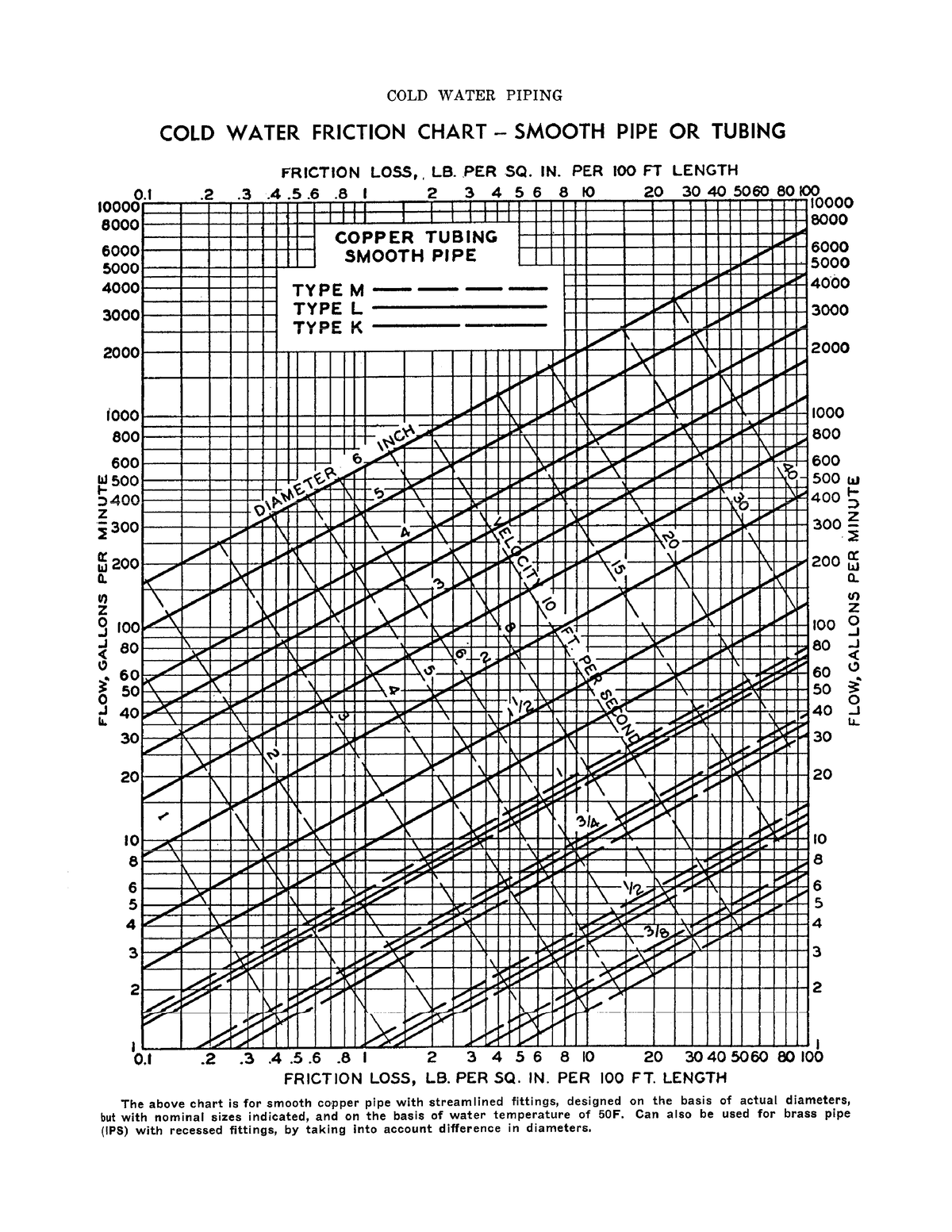

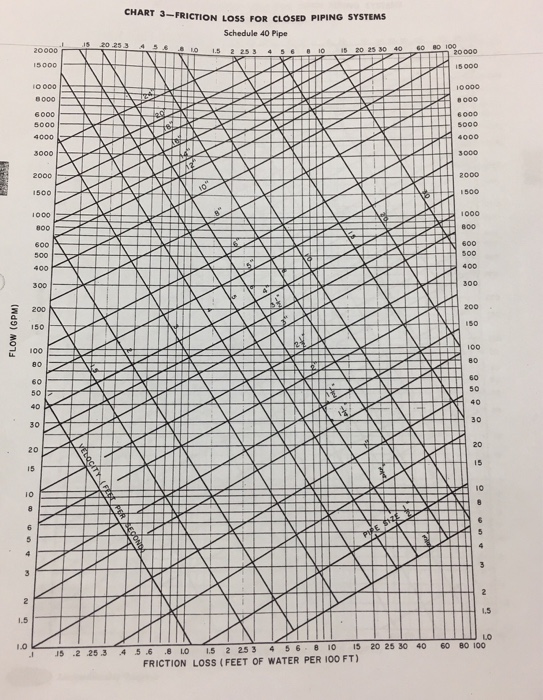

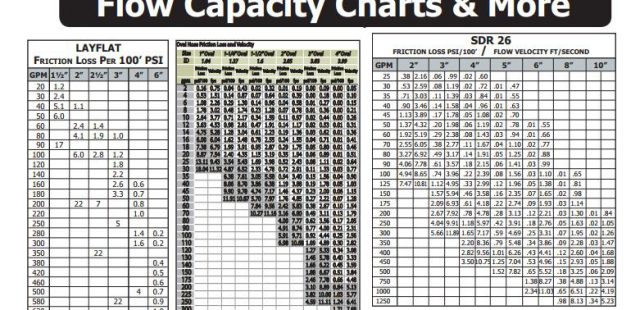

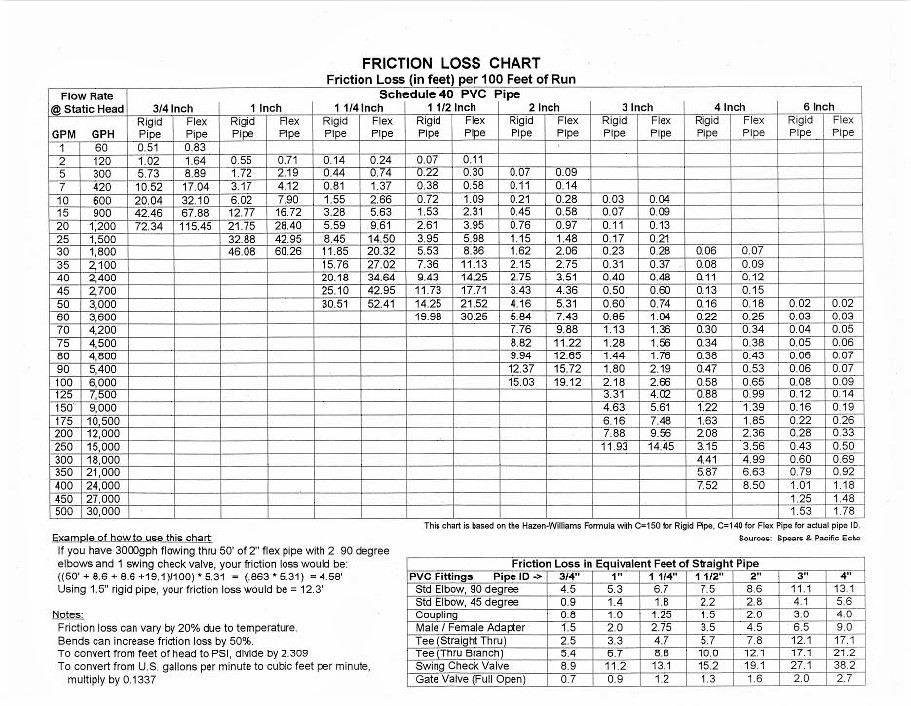

Friction loss charts usually current information in tabular or graphical kind, relating circulate fee (typically in gallons per minute or GPM), pipe diameter (in inches), and friction loss (often in toes of head per 100 toes of pipe or psi per 100 toes). These charts are sometimes particular to a specific fluid, often water at a normal temperature (e.g., 68°F or 20°C). The Hazen-Williams equation or the Darcy-Weisbach equation are generally used to generate these charts.

Utilizing a Typical Friction Loss Chart:

A typical chart would possibly seem as follows (Notice: This can be a simplified instance and precise charts are extra detailed):

| Pipe Diameter (inches) | Circulation Charge (GPM) | Friction Loss (ft/100ft) |

|---|---|---|

| 1 | 10 | 5 |

| 1 | 20 | 20 |

| 2 | 10 | 0.5 |

| 2 | 20 | 2 |

| 3 | 10 | 0.1 |

| 3 | 20 | 0.8 |

To make use of this chart, find the specified pipe diameter. Then, discover the corresponding circulate fee. The intersection of those values supplies the friction loss in toes of head per 100 toes of pipe. For instance, a 1-inch diameter pipe carrying 10 GPM experiences a friction lack of 5 toes per 100 toes of pipe.

Changing Friction Loss Items:

Friction loss is usually expressed in several models, requiring conversion for consistency. Frequent models embody:

- Ft of head per 100 toes: This represents the vertical distance the fluid would rise because of the strain loss.

- Kilos per sq. inch (psi) per 100 toes: This represents the strain drop in psi over a 100-foot size.

- Meters of head per 100 meters: The metric equal of toes of head per 100 toes.

- Pascals (Pa) per meter: The metric equal of psi per 100 toes.

Conversion elements are wanted to maneuver between these models, and these elements depend upon the fluid’s density and the acceleration as a result of gravity.

Accounting for Fittings and Valves:

Friction loss charts usually solely account for the straight pipe sections. Fittings and valves introduce extra resistance. To compensate, their contribution is expressed as an equal size of straight pipe. Producers present equal size information for his or her particular fittings. This equal size is added to the whole pipe size earlier than consulting the friction loss chart.

Making use of Friction Loss Calculations in System Design:

The method of designing a PVC piping system entails a number of steps:

- Decide the required circulate fee: This depends upon the appliance, such because the water demand for a home or the circulate fee wanted for an irrigation system.

- Choose the pipe diameter: Select a diameter that minimizes friction loss whereas contemplating price and area constraints.

- Calculate the whole pipe size: Embrace each straight pipe sections and the equal lengths of fittings and valves.

- Decide the friction loss: Use the friction loss chart to search out the strain drop based mostly on the chosen pipe diameter, circulate fee, and whole pipe size.

- Account for elevation modifications: If the pipe runs uphill, the pump wants to beat the extra head as a result of gravity. Conversely, downhill sections scale back the strain drop.

- Choose the pump (if wanted): The pump should present ample strain to beat the whole friction loss and elevation modifications, making certain ample strain on the discharge level.

Software program and On-line Calculators:

Many software program packages and on-line calculators can be found to simplify friction loss calculations. These instruments typically incorporate extra complicated equations and account for a wider vary of things, together with fluid temperature and viscosity variations.

Conclusion:

Understanding and making use of Schedule 40 PVC friction loss charts is important for environment friendly and dependable piping system design. By contemplating the elements influencing friction loss and utilizing applicable charts or calculation instruments, engineers and designers can make sure that methods function optimally, avoiding undersized pipes, extreme strain drops, and potential system failures. Keep in mind to all the time seek the advice of producer’s information and think about the precise software necessities for correct and secure system design. Whereas this text supplies a complete overview, in search of skilled engineering recommendation for complicated initiatives is all the time advisable.

Closure

Thus, we hope this text has offered worthwhile insights into Decoding the Schedule 40 PVC Friction Loss Chart: A Complete Information. We hope you discover this text informative and useful. See you in our subsequent article!