Management Charts: Unveiling the Variations Between Management Charts and P-Charts for Course of Monitoring

Associated Articles: Management Charts: Unveiling the Variations Between Management Charts and P-Charts for Course of Monitoring

Introduction

With nice pleasure, we are going to discover the intriguing subject associated to Management Charts: Unveiling the Variations Between Management Charts and P-Charts for Course of Monitoring. Let’s weave fascinating data and supply contemporary views to the readers.

Desk of Content material

Management Charts: Unveiling the Variations Between Management Charts and P-Charts for Course of Monitoring

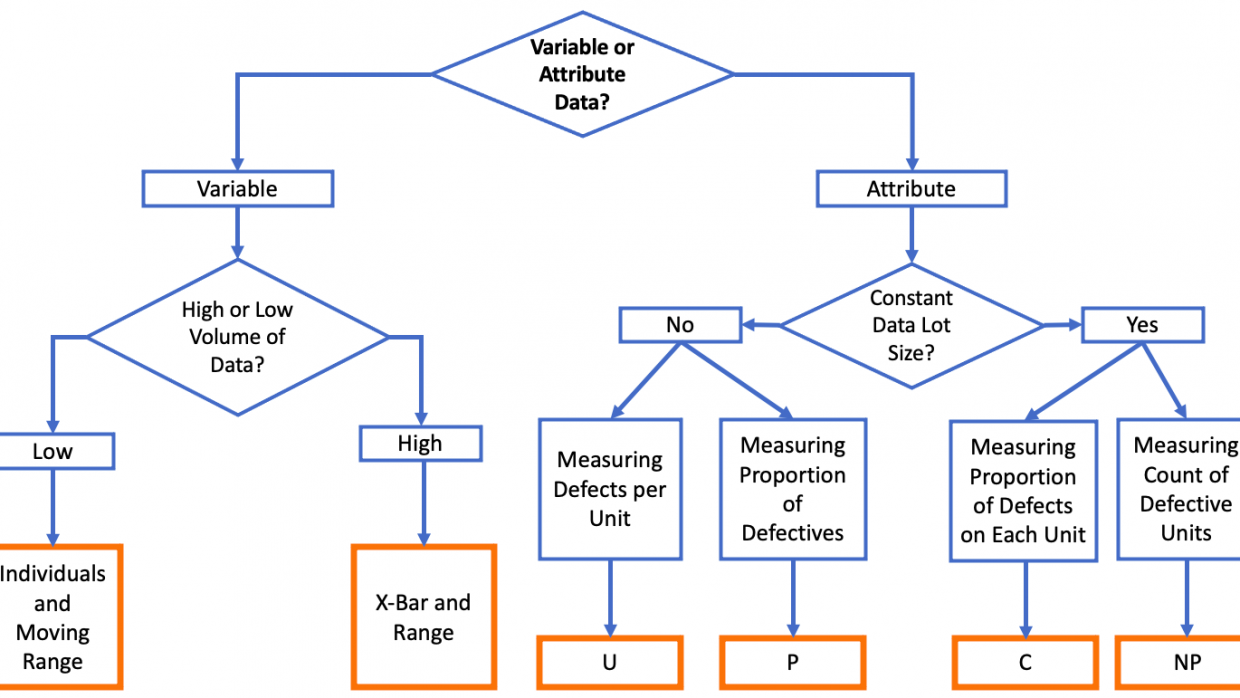

Statistical Course of Management (SPC) is an important methodology for monitoring and bettering processes. A cornerstone of SPC is using management charts, graphical instruments that show information over time, permitting for the identification of developments and patterns indicative of course of instability. Among the many numerous sorts of management charts, two stand out as a consequence of their frequent software: management charts for variables (usually referred to easily as "management charts") and p-charts (management charts for attributes). Whereas each serve the aim of course of monitoring, they differ considerably in the kind of information they analyze and the knowledge they supply. This text delves into the distinctions between management charts and p-charts, highlighting their purposes, development, and interpretation.

Management Charts for Variables (X-bar and R Charts): Monitoring Steady Knowledge

Management charts for variables are used when the method attribute being monitored is a steady variable. This implies the info can tackle any worth inside a variety, corresponding to weight, size, temperature, or strain. These charts usually encompass two charts utilized in conjunction: the X-bar chart and the R chart (or s chart for bigger pattern sizes).

-

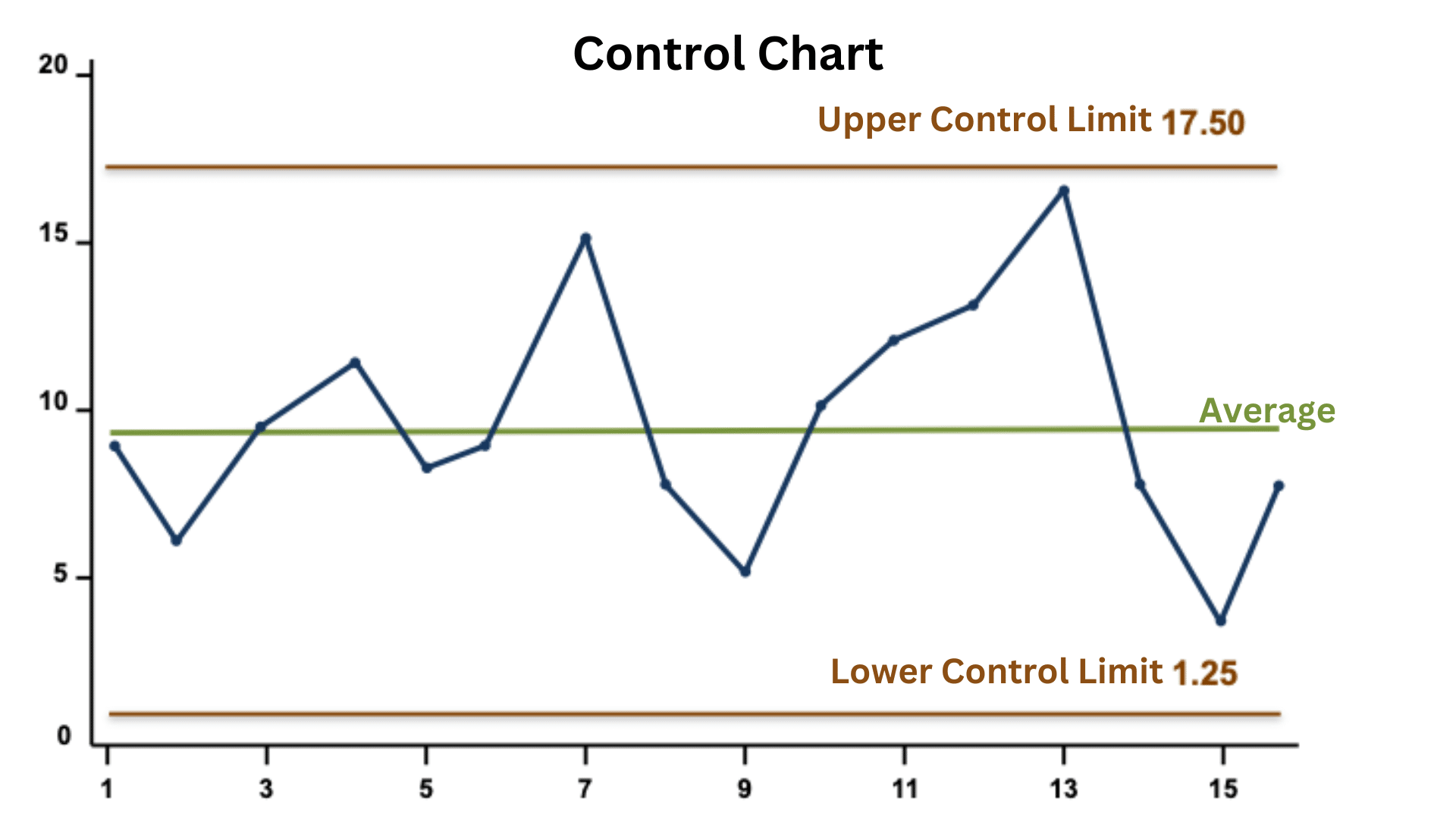

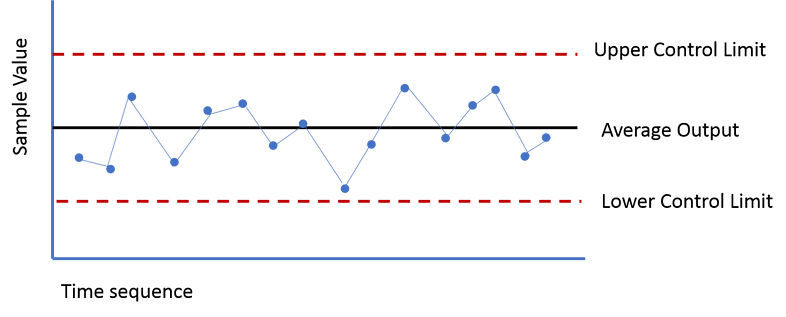

X-bar chart: This chart screens the common (imply) of the method attribute. Every level on the chart represents the common of a pattern taken from the method. The middle line represents the general common of the method, whereas the higher and decrease management limits (UCL and LCL) outline the suitable vary of variation. Factors exterior these limits sign a possible course of shift or particular trigger variation.

-

R chart (or s chart): This chart screens the vary (or commonplace deviation) of the method attribute inside every pattern. The vary represents the distinction between the most important and smallest values in a pattern. The R chart helps detect adjustments within the course of variability. A steady course of will exhibit constant variability, whereas an unstable course of will present fluctuations within the vary. The s chart makes use of the usual deviation as a substitute of the vary, providing a extra statistically sturdy measure of variability, particularly for bigger pattern sizes.

Development of X-bar and R Charts:

The development of X-bar and R charts entails the next steps:

- Knowledge Assortment: Acquire information from the method in subgroups (samples) of a constant dimension (usually 4-5 observations per subgroup).

- Calculate Statistics: For every subgroup, calculate the common (X-bar) and vary (R) or commonplace deviation (s).

- Calculate General Statistics: Calculate the general common of the X-bar values (X-double bar) and the common vary (R-bar) or common commonplace deviation (s-bar) throughout all subgroups.

- Decide Management Limits: Use applicable management chart constants (A2, D3, D4 for R charts; A3, B3, B4 for s charts) and the general statistics to calculate the UCL and LCL for each the X-bar and R (or s) charts. These constants are available in statistical tables or software program packages.

- Plot the Knowledge: Plot the X-bar and R (or s) values on their respective charts.

Interpretation of X-bar and R Charts:

The interpretation of those charts entails in search of factors exterior the management limits or patterns throughout the information that counsel instability. Factors exterior the management limits point out a possible particular reason behind variation, warranting investigation. Patterns corresponding to developments, cycles, or stratification additionally counsel course of instability.

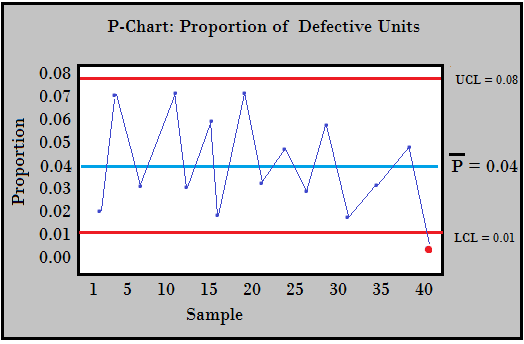

P-Charts: Monitoring Proportion Nonconforming

P-charts are used when the method attribute being monitored is an attribute, particularly the proportion of nonconforming items in a pattern. This implies the info is categorical, representing whether or not a unit meets a specification (conforming) or doesn’t (nonconforming). For example, a p-chart would possibly monitor the proportion of faulty gadgets produced on an meeting line or the proportion of buyer complaints.

Development of P-Charts:

The development of p-charts entails the next steps:

- Knowledge Assortment: Acquire information in subgroups of a constant dimension. For every subgroup, depend the variety of nonconforming items.

- Calculate Proportions: For every subgroup, calculate the proportion of nonconforming items (p) by dividing the variety of nonconforming items by the subgroup dimension.

- Calculate General Proportion: Calculate the general proportion of nonconforming items (p-bar) throughout all subgroups.

- Decide Management Limits: The management limits for a p-chart are calculated utilizing the general proportion and the subgroup dimension. The formulation incorporate the binomial distribution’s traits.

- Plot the Knowledge: Plot the p values on the p-chart.

Interpretation of P-Charts:

Much like X-bar and R charts, factors exterior the management limits or patterns throughout the information counsel course of instability. Factors above the UCL point out a rise within the proportion of nonconforming items, whereas factors beneath the LCL (although much less widespread and infrequently ignored because of the nature of proportions) point out a lower. Patterns like developments or cycles warrant investigation to determine the foundation reason behind the variation.

Key Variations Between Management Charts and P-Charts:

| Function | Management Charts (X-bar and R) | P-Charts |

|---|---|---|

| Knowledge Sort | Steady Variables | Attribute Knowledge (Proportion Nonconforming) |

| Measurement | Numerical Values | Proportion or Proportion |

| Chart Sort | X-bar chart & R (or s) chart | Single P-chart |

| Focus | Course of Imply and Variability | Proportion of Nonconforming Models |

| Pattern Measurement | Comparatively constant | Can fluctuate, however constant inside subgroups |

| Management Limits | Based mostly on imply and vary/std. dev. | Based mostly on binomial distribution |

Selecting the Proper Chart:

The selection between management charts and p-charts relies upon completely on the kind of information being collected. If the method attribute is a steady variable, management charts are applicable. If the method attribute is an attribute representing the proportion of nonconforming items, a p-chart is the appropriate alternative. Incorrect chart choice can result in deceptive conclusions and ineffective course of enchancment efforts.

Past the Fundamentals: Superior Issues

Each management charts and p-charts might be enhanced with extra refined strategies. For example, CUSUM (cumulative sum) and EWMA (exponentially weighted transferring common) charts supply larger sensitivity to small shifts within the course of imply. For p-charts, np-charts (monitoring the variety of nonconforming items) are used when the subgroup dimension is fixed. Moreover, the choice of applicable subgroup sizes is essential for efficient management chart implementation. Subgroups must be chosen to characterize the method’s pure variation and to attenuate the affect of extraneous elements.

Conclusion:

Management charts and p-charts are indispensable instruments in statistical course of management, providing worthwhile insights into course of efficiency and stability. Understanding their variations, development, and interpretation is essential for successfully monitoring and bettering processes. By rigorously choosing the suitable chart and analyzing the ensuing information, organizations can determine sources of variation, scale back defects, and improve total course of effectivity. The choice of the correct chart hinges on the character of the info: steady for management charts and attribute (proportion) for p-charts. Correct software of those charts results in data-driven decision-making and steady enchancment.

Closure

Thus, we hope this text has offered worthwhile insights into Management Charts: Unveiling the Variations Between Management Charts and P-Charts for Course of Monitoring. We respect your consideration to our article. See you in our subsequent article!