Decoding the 411 Fast Change Gear Chart: A Complete Information

Associated Articles: Decoding the 411 Fast Change Gear Chart: A Complete Information

Introduction

With enthusiasm, let’s navigate by way of the intriguing subject associated to Decoding the 411 Fast Change Gear Chart: A Complete Information. Let’s weave attention-grabbing info and supply recent views to the readers.

Desk of Content material

Decoding the 411 Fast Change Gear Chart: A Complete Information

The 411 fast change gearbox, a marvel of mechanical engineering, provides unparalleled versatility in machining operations. Its capacity to swiftly alter spindle speeds with out stopping the machine dramatically will increase effectivity and productiveness. Nevertheless, understanding the intricacies of its gear chart is essential for maximizing its potential. This text dives deep into the 411 fast change gear chart, explaining its construction, how one can interpret it, and how one can choose the proper gear mixture for varied machining duties. We’ll additionally discover widespread functions, troubleshooting ideas, and some great benefits of this method over conventional gearboxes.

Understanding the 411 Fast Change Gearbox System

The 411 fast change gearbox is a sort of stepped transmission system generally present in lathes and milling machines. In contrast to gearboxes requiring particular person gear modifications for every pace, the 411 system makes use of a set of simply interchangeable gears, permitting for fast pace changes. That is achieved by way of a sequence of exactly designed gears organized in a particular configuration, often involving a fundamental drive gear, intermediate gears, and a pushed gear linked to the spindle. The association of those gears determines the ultimate pace ratio and, consequently, the spindle pace.

The "411" designation would not check with a particular variety of gears however somewhat to a standard configuration or association of gears throughout the gearbox. Completely different producers would possibly use barely various inner designs, however the elementary precept stays the identical: fast pace modifications by way of a system of simply interchangeable gears. The chart itself is the important thing to unlocking this method’s potential.

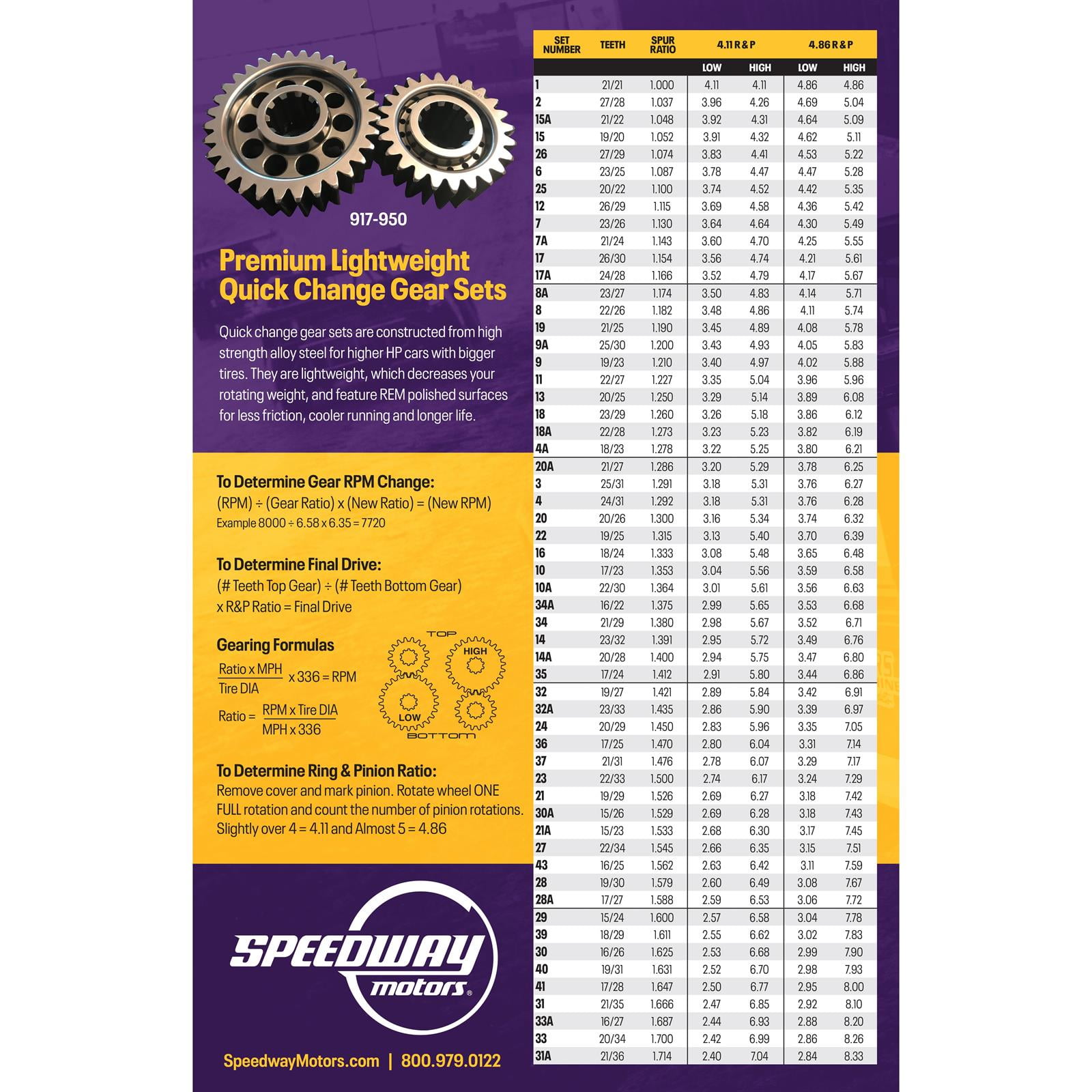

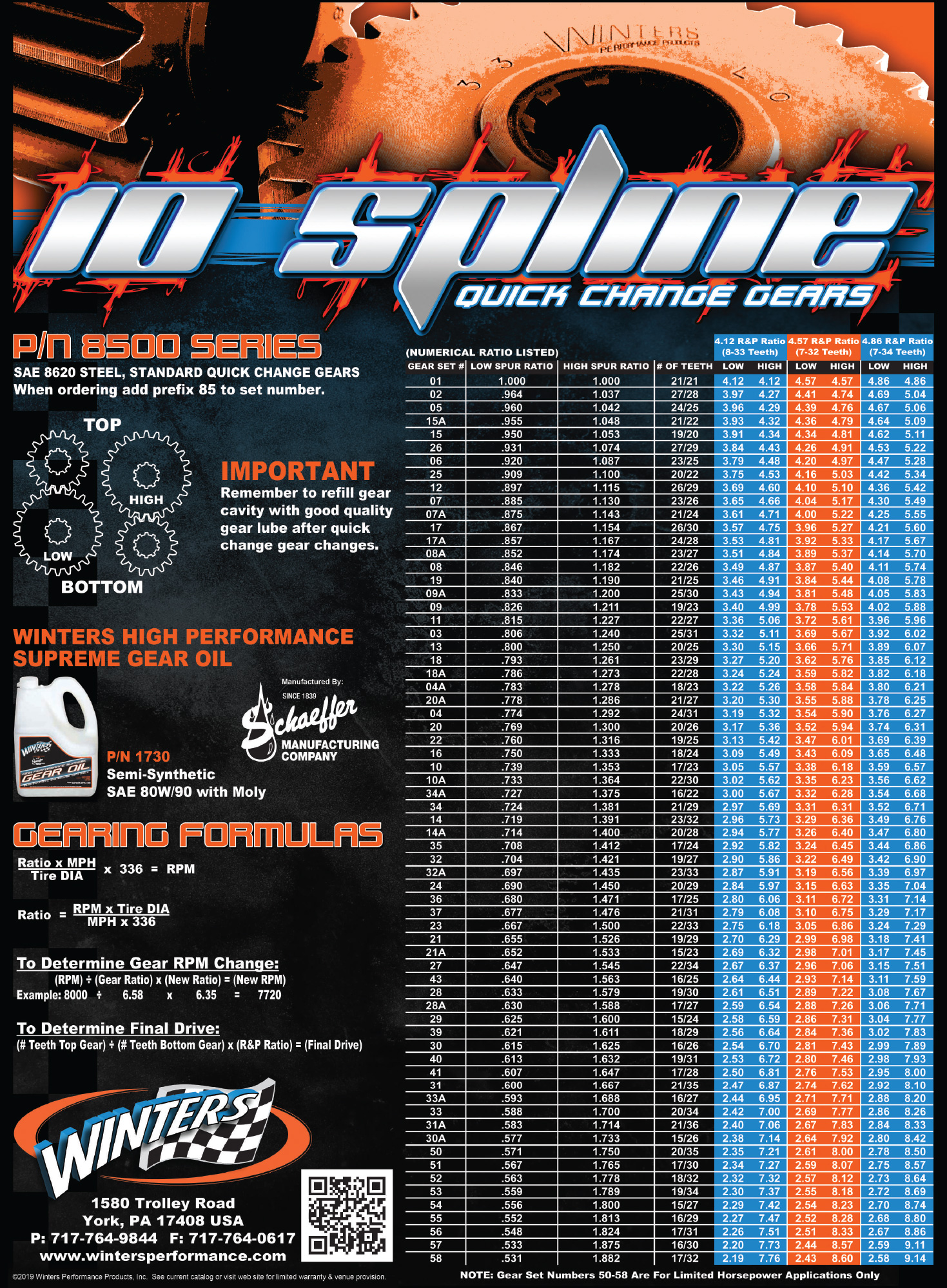

Construction of the 411 Fast Change Gear Chart

A typical 411 fast change gear chart is a desk organized to point out the connection between:

- Gear Choice: This means which gears (recognized by numbers or letters) have to be engaged to attain a particular spindle pace. It often lists the gear numbers for each the intermediate and pushed gears.

- Spindle Velocity (RPM): That is the ensuing rotational pace of the machine’s spindle, expressed in revolutions per minute (RPM). That is instantly depending on the motor pace and the gear ratio.

- Motor Velocity (RPM): The pace at which the motor driving the gearbox is working. That is typically a continuing worth, however some techniques would possibly permit for motor pace changes.

- Again Gear Engagement: Some 411 gearboxes incorporate a again gear mechanism, which offers a decrease vary of speeds. The chart will sometimes point out whether or not the again gear must be engaged or disengaged for every pace choice.

- Feed Price (Optionally available): Superior charts can also embrace details about the corresponding feed charges for various spindle speeds, notably related for milling operations.

Deciphering the 411 Fast Change Gear Chart

Deciphering the chart is easy when you perceive its construction. Let’s think about a hypothetical instance:

| Gear Choice (Intermediate/Pushed) | Spindle Velocity (RPM) | Motor Velocity (RPM) | Again Gear |

|---|---|---|---|

| 1/1 | 1000 | 1000 | Disengaged |

| 2/2 | 500 | 1000 | Disengaged |

| 3/3 | 333 | 1000 | Disengaged |

| 1/2 | 2000 | 1000 | Disengaged |

| 1/3 | 3000 | 1000 | Disengaged |

| 1/1 | 500 | 1000 | Engaged |

| 2/1 | 250 | 1000 | Engaged |

| 3/1 | 167 | 1000 | Engaged |

On this instance:

- To realize a spindle pace of 500 RPM with the motor working at 1000 RPM, you’d have interaction intermediate gear 2 and pushed gear 2, maintaining the again gear disengaged.

- For a slower pace of 250 RPM, you’d have interaction intermediate gear 2 and pushed gear 1, with the again gear engaged.

The chart offers a direct mapping between gear combos and spindle speeds, simplifying the method of choosing the suitable pace for a given machining operation.

Deciding on the Appropriate Gear Mixture

The number of the proper gear mixture relies upon totally on the fabric being machined, the reducing software getting used, and the specified floor end. Tougher supplies usually require decrease spindle speeds and heavier feeds, whereas softer supplies can tolerate larger speeds. The reducing software’s geometry and materials additionally affect the optimum pace. Seek the advice of the producer’s suggestions in your particular reducing instruments and supplies. place to begin is to decide on a pace throughout the advisable vary for the fabric and gear mixture, then alter as wanted based mostly on the precise machining course of.

Widespread Purposes of 411 Fast Change Gearboxes

411 fast change gearboxes discover widespread use in varied machining functions, together with:

- Lathe Operations: Turning, going through, boring, threading. The flexibility to shortly change speeds is essential for optimizing reducing parameters for various operations and supplies.

- Milling Operations: Face milling, finish milling, slot milling. The flexibility in pace choice permits for environment friendly machining of assorted supplies and geometries.

- Drilling Operations: Drilling holes of various sizes and depths. The correct pace management ensures optimum drilling efficiency and prevents software breakage.

- Normal Objective Machining: The gearbox’s adaptability makes it appropriate for a variety of machining duties.

Troubleshooting Widespread Points

Regardless of their strong design, 411 fast change gearboxes can generally expertise points. Some widespread issues and their options embrace:

- Gear Noise: Extreme noise typically signifies worn gears, improper lubrication, or free fasteners. Examine the gears for put on, lubricate the gearbox correctly, and tighten all fasteners.

- Spindle Velocity Inaccuracy: This may be as a consequence of incorrect gear choice, a malfunctioning motor, or an issue with the gearbox mechanism. Double-check the gear chart, examine the motor, and study the gearbox for any mechanical points.

- Gear Shifting Problem: Stiff shifting could possibly be attributable to worn gears, lack of lubrication, or particles within the gearbox. Lubricate the gearbox, clear any particles, and think about changing worn gears if obligatory.

Benefits over Conventional Gearboxes

In comparison with conventional gearboxes, the 411 fast change system provides a number of key benefits:

- Elevated Effectivity: Speedy pace modifications reduce downtime and improve total productiveness.

- Decreased Setup Time: Switching between totally different speeds is far quicker and simpler.

- Improved Accuracy: Exact gear choice ensures correct spindle speeds, main to raised machining accuracy.

- Versatility: The wide selection of speeds permits for machining a wide range of supplies and elements.

Conclusion

The 411 fast change gear chart is an important software for anybody working with a 411 gearbox. Understanding its construction, how one can interpret it, and how one can choose the proper gear combos is essential for maximizing the gearbox’s capabilities and reaching optimum machining outcomes. By following the rules offered on this article and training secure machining strategies, operators can considerably improve their effectivity and produce high-quality workpieces. Common upkeep and a spotlight to potential points will make sure the longevity and dependable efficiency of this helpful piece of machining gear. All the time check with the producer’s particular directions and security tips in your explicit machine and gearbox mannequin.

Closure

Thus, we hope this text has offered helpful insights into Decoding the 411 Fast Change Gear Chart: A Complete Information. We thanks for taking the time to learn this text. See you in our subsequent article!