Unveiling the Pareto Precept: A Deep Dive into Pareto Charts and Their Software in High quality Management

Associated Articles: Unveiling the Pareto Precept: A Deep Dive into Pareto Charts and Their Software in High quality Management

Introduction

With enthusiasm, let’s navigate by way of the intriguing subject associated to Unveiling the Pareto Precept: A Deep Dive into Pareto Charts and Their Software in High quality Management. Let’s weave attention-grabbing info and provide contemporary views to the readers.

Desk of Content material

Unveiling the Pareto Precept: A Deep Dive into Pareto Charts and Their Software in High quality Management

The seven primary high quality management instruments present a foundational framework for understanding and bettering processes. Amongst these, the Pareto chart stands out as a strong visible device for prioritizing problem-solving efforts. Primarily based on the Pareto precept, also called the 80/20 rule, it highlights the important few components contributing to nearly all of issues, permitting for targeted and environment friendly enchancment initiatives. This text will discover the Pareto chart intimately, inspecting its development, interpretation, and functions inside the context of the seven QC instruments.

Understanding the Pareto Precept

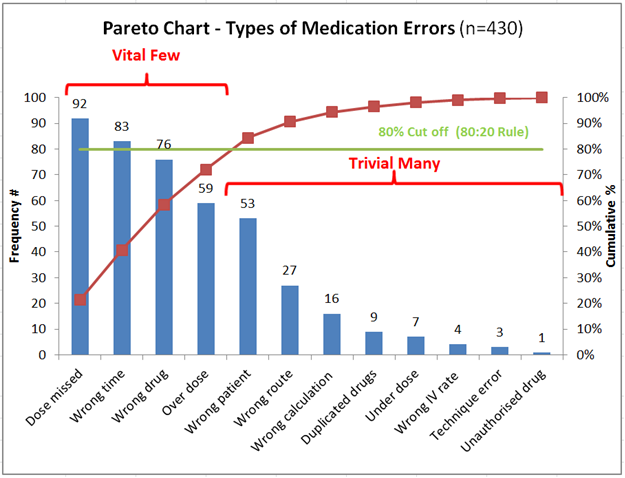

Earlier than delving into the specifics of the chart, it is essential to understand the underlying precept: the Pareto precept. This precept, noticed throughout varied fields, means that roughly 80% of results come from 20% of causes. Within the context of high quality management, this interprets to the concept a small share of defects or issues account for a good portion of general high quality points. As an illustration, 80% of buyer complaints would possibly stem from 20% of the recognized product defects. Figuring out this significant 20% is the place the Pareto chart turns into invaluable.

Establishing a Pareto Chart: A Step-by-Step Information

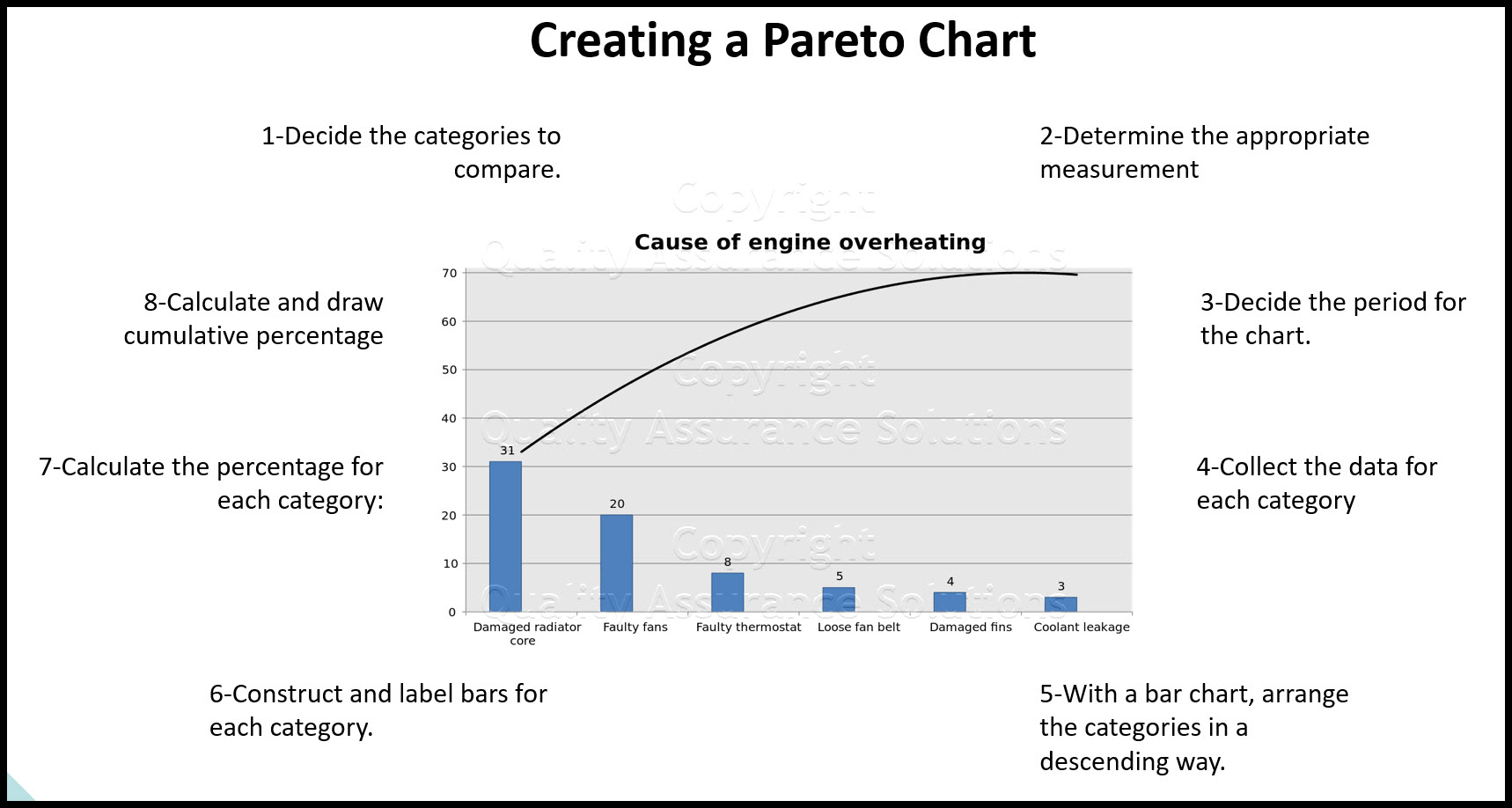

Making a Pareto chart includes a scientific course of:

-

Information Assortment and Categorization: Step one includes accumulating knowledge associated to the issue being investigated. This knowledge may characterize defects, complaints, errors, or some other related metric. It is essential to categorize this knowledge into distinct, mutually unique classes. For instance, if analyzing buyer complaints, classes would possibly embrace "product malfunction," "transport harm," "poor customer support," and so on.

-

Information Tabulation and Frequency Calculation: As soon as categorized, the info must be tabulated to find out the frequency of prevalence for every class. This includes counting the variety of occurrences for every class.

-

Calculating Cumulative Frequency: The following step is calculating the cumulative frequency for every class. This includes including the frequency of every class to the sum of the frequencies of all previous classes. This cumulative frequency is essential for visualizing the Pareto precept.

-

Calculating Percentages: Convert the frequency of every class right into a share of the overall variety of occurrences. Equally, calculate the cumulative share for every class.

-

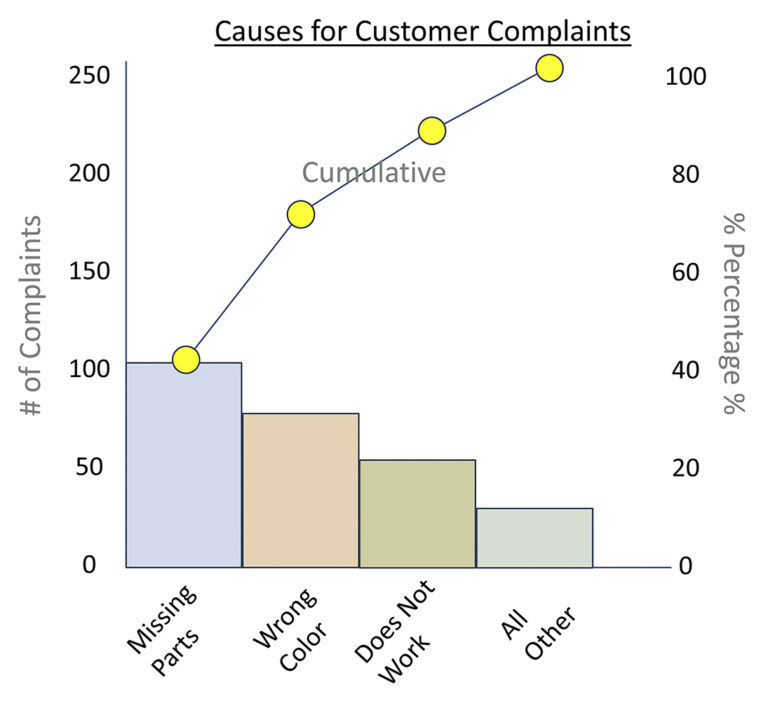

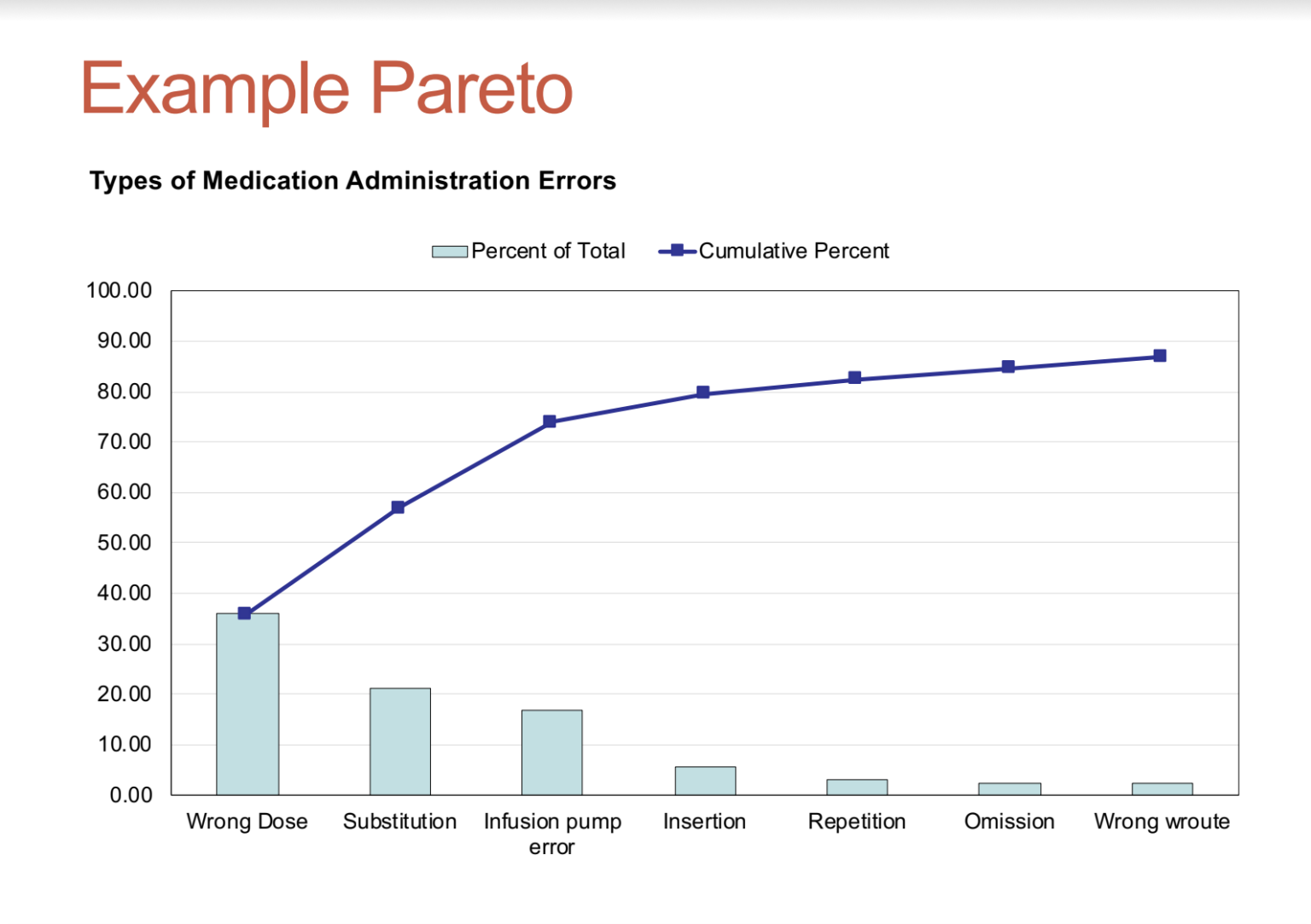

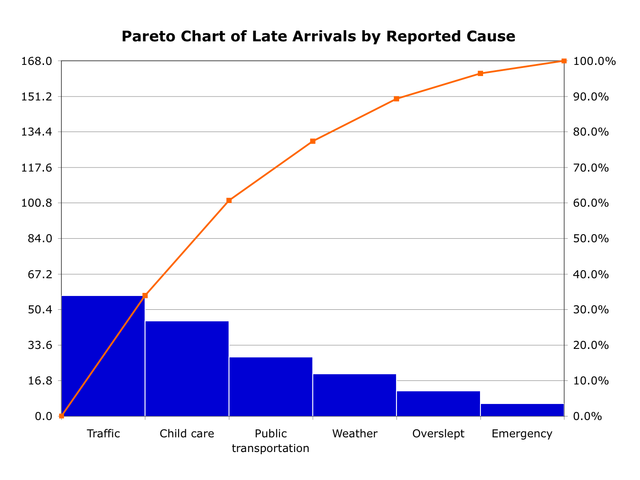

Chart Building: The Pareto chart itself is a mix of a bar chart and a line graph. The bar chart represents the frequency of every class, organized in descending order from left to proper (highest frequency to lowest). The road graph, overlaid on the bar chart, represents the cumulative share.

-

Labeling and Titling: The chart must be clearly labeled with a title indicating the issue being analyzed, and every bar must be labeled with its corresponding class and frequency. The y-axis ought to characterize each frequency and cumulative share, whereas the x-axis represents the classes.

Deciphering a Pareto Chart: Figuring out the Very important Few

The Pareto chart’s energy lies in its visible illustration of the Pareto precept. By arranging classes in descending order of frequency and displaying the cumulative share, it instantly highlights the "important few" classes accountable for almost all of issues. The steep preliminary rise of the cumulative share line clearly signifies these dominant classes.

As an illustration, if the cumulative share reaches 80% after solely three classes, it means that focusing enchancment efforts on these three classes will yield essentially the most important influence on general high quality. Ignoring the remaining classes, whereas they contribute to the issue, can be a much less environment friendly use of sources.

Purposes of Pareto Charts in High quality Management

Pareto charts discover widespread utility throughout varied high quality management situations:

-

Defect Evaluation: Figuring out essentially the most frequent kinds of defects in a producing course of. This enables for focused enhancements to scale back essentially the most prevalent defects.

-

Buyer Grievance Evaluation: Pinpointing the principle sources of buyer dissatisfaction. This helps corporations tackle essentially the most urgent buyer issues and enhance general buyer satisfaction.

-

Course of Enchancment: Figuring out the important thing bottlenecks or areas of inefficiency in a course of. This enables for targeted enhancements to streamline the method and improve effectivity.

-

Security Incident Evaluation: Figuring out the commonest causes of security incidents in a office. This facilitates the event of focused security measures to scale back accidents.

-

Root Trigger Evaluation: Used at the side of different high quality instruments like fishbone diagrams (Ishikawa diagrams) to delve deeper into the foundation causes of the recognized issues. The Pareto chart helps prioritize which causes to research first.

Pareto Charts in Conjunction with Different Seven QC Instruments

The Pareto chart is handiest when used at the side of different seven QC instruments. For instance:

-

Examine Sheets: Examine sheets present the uncooked knowledge that feeds into the Pareto chart. They facilitate systematic knowledge assortment and categorization.

-

Histograms: Histograms present a visible illustration of the distribution of knowledge inside every class recognized within the Pareto chart. This offers a extra granular understanding of the issue.

-

Scatter Diagrams: Scatter diagrams will help establish potential correlations between variables contributing to the issues highlighted within the Pareto chart.

-

Management Charts: Management charts can monitor the effectiveness of enchancment initiatives carried out based mostly on the insights gained from the Pareto chart.

-

Trigger-and-Impact Diagrams (Fishbone Diagrams): Used to discover the foundation causes of the important few issues recognized by the Pareto chart.

-

Stratification: Stratification can be utilized to section the info earlier than making a Pareto chart, permitting for a deeper understanding of the issue’s varied facets. As an illustration, stratifying by shift, machine, or operator can reveal patterns not obvious in aggregated knowledge.

Limitations of Pareto Charts

Whereas highly effective, Pareto charts have sure limitations:

-

Oversimplification: The 80/20 rule is a suggestion, not a inflexible regulation. The precise proportions might fluctuate.

-

Information Dependence: The effectiveness of the chart depends on correct and complete knowledge assortment. Inaccurate or incomplete knowledge can result in deceptive conclusions.

-

Lack of Context: The chart does not present detailed explanations for the recognized issues. Additional investigation is critical to know the underlying causes.

Conclusion

The Pareto chart, a cornerstone of the seven QC instruments, provides a strong visible strategy to prioritizing problem-solving efforts. By highlighting the important few components contributing to nearly all of issues, it permits targeted useful resource allocation and environment friendly enchancment initiatives. Nonetheless, it is essential to keep in mind that the Pareto chart is handiest when used at the side of different QC instruments and interpreted inside the applicable context. By understanding its strengths and limitations, organizations can leverage the Pareto chart to considerably enhance high quality, effectivity, and general efficiency. Its utility extends far past manufacturing and high quality management, proving a beneficial device in varied fields striving for steady enchancment.

Closure

Thus, we hope this text has offered beneficial insights into Unveiling the Pareto Precept: A Deep Dive into Pareto Charts and Their Software in High quality Management. We recognize your consideration to our article. See you in our subsequent article!